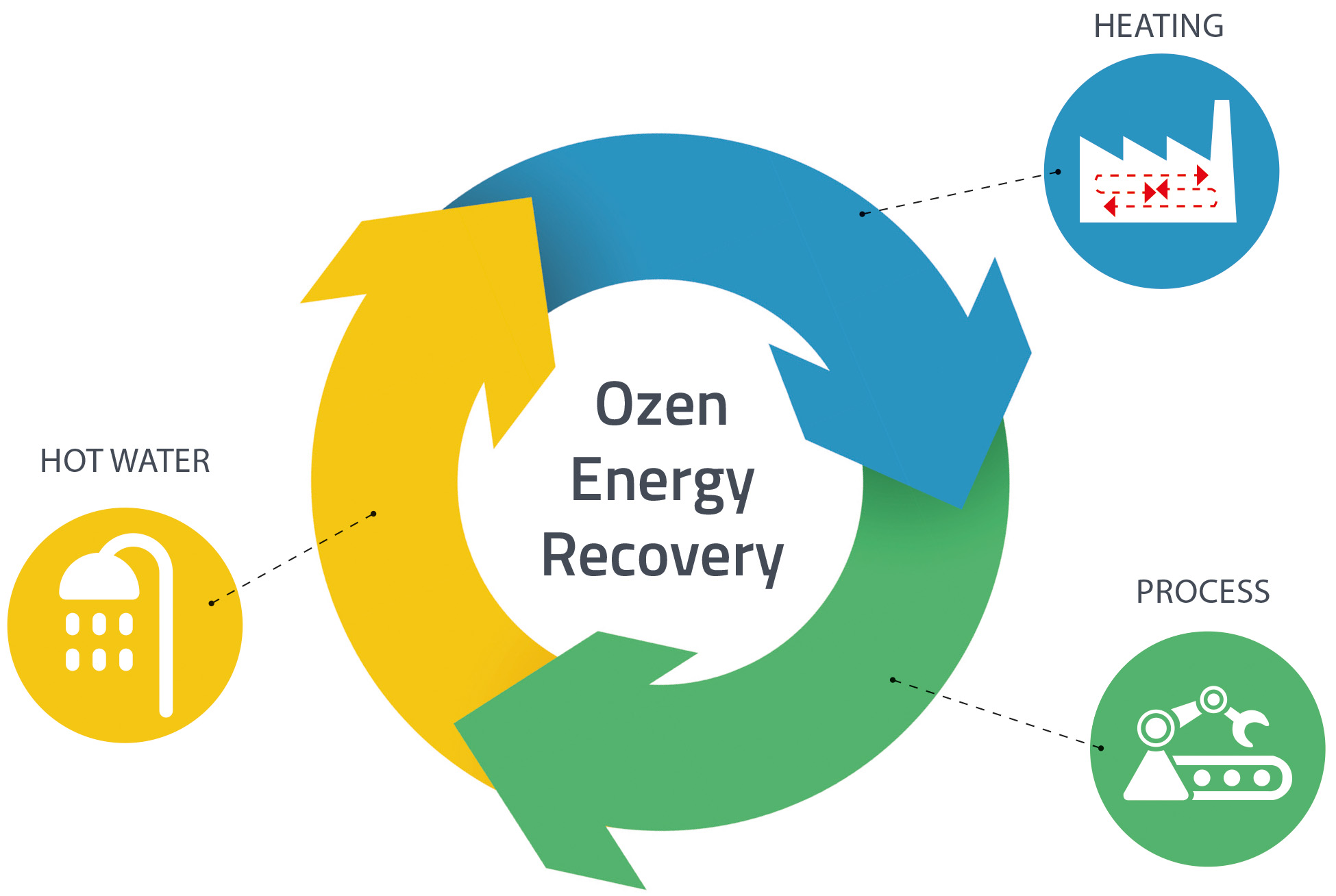

Ozen Energy Recovery

Reduces operating costs by

recovering waste heat…

Improving energy efficiency is essential for the industry. Rising energy prices and growing environmental awareness increase the importance of waste heat recovery. 94% of the energy consumed by a compressor is converted into heat. This heat is released back into the atmosphere through the cooling system and by radiation. Not being able to make use of this waste heat has a negative effect on operating costs.

Ozen Energy Recovery solution makes it possible to use the waste heat generated by your compressor within the facility. The integrated heat exchanger recovers the heat, which can, then, be used for heating the factory and storage areas, as well as for hot water. This rather easy to implement system increases energy efficiency and provides operating cost savings.

Advantages

- Does not have any impact on compressor maintenance.

- Return of investment is 1 year.

- Reduces gas etc. consumption for heating and hot water

- Selecting for heat recovery not only lowers energy costs but also contributes greatly to the protection of the environment.